we are the composite tailors

Back to list

Back to list

Customer demand

Long-fiber-reinforced heat-curing CFRP was originally not suitable for mass production of traditional computer casings. However, we have received requests from customers that they hope to mass-produce computer casings with light weight advantages. In addition, electronic products have high flame resistance requirements in terms of safety performance, and we must meet this requirement.

The key to solving the problem

R&D of fast curing, flame retardant resin and fully automatic mass production production line

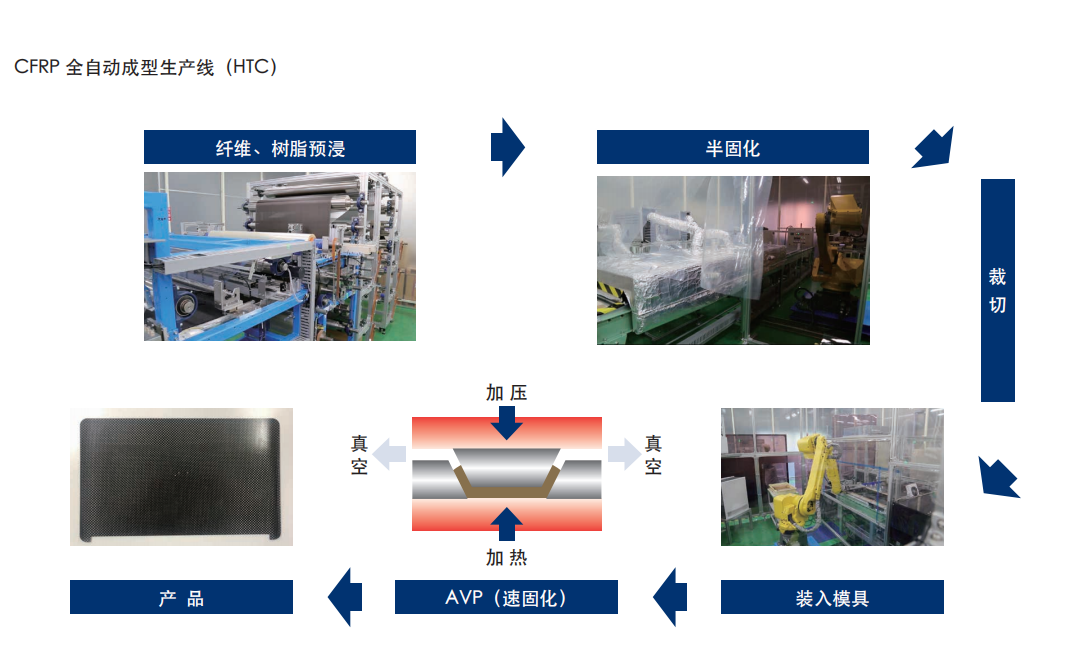

We have developed a fast-curing resin to enable mass production of CFRP and give it flame-retardant properties. In addition, in order to meet the multiple requirements of production quantity, cost and appearance, the company has developed a new fully automatic mass production line, from the resin prepreg of the fiber base material, to the layering, heating and pressure curing, processing, etc., a consistent automatic Complete, no labor is required.

Through the study of the molecular structure of epoxy resin, we have achieved the optimization of curing speed and heat resistance temperature, and successfully developed a fast curing resin that cures in 2 minutes. In addition, by adjusting the type and amount of additives to the resin, a highly flame-retardant (equivalent to UL-94 V0) resin was successfully born.

We put the resin into the fully automated CFRP mass production line (High Throughput Composite: HTC) newly developed by the mass production engineering team, and achieved actual production results of 10,000 units/line/month.

From the research and development of the flame-retardant resin to the design and application of the production line, we carry out consistent research and development in order to realize the demands of our customers. This is our "tailor-made".

Compared with aluminum, composite materials are lighter and harder. The use of CFRP can achieve the requirements of ultra-thin, lightweight, mega-size, and strength enhancement of electrical products. The use of carbon fiber trims in high-end models of electronic products has also become a popular trend. Our products include mobile phone shells, notebook computer panels, flat panel display back panels, etc.

In addition, in order to meet production demand, the company has independently developed and obtained patents for the CFRP mass production line (HTC), which combines mechatronics and fast curing resin technology, has been put into use and has rich production experience.

Product Center

Automotive field Industrial machinery field Aerospace Electrical product field Sports field Environment and urban constructionContact Us

0574-8838-5544